Our Company

ABOUT US

Elevating glass innovations globally

Mediterranean Float Glass (MFG SPA), a subsidiary of the CEVITAL group, was created in 2007 and is led by a team of young talents dedicated to progress and development. Today, MFG is one of Africa's leading glass producers. Located in Arbâa, Wilaya of Blida, just 32 km from the port of Algiers, the head office and factory cover an area of 30 hectares.

In its first year of existence, MFG transformed Algeria from an exclusive importer of flat glass to an exporter, satisfying more than 90% of local demand. Beyond Algeria, MFG serves international markets, particularly in the Maghreb and Southern Europe, with notable expansion thanks to a second float line in 2017.

Production

Rapid Growth and Expansion of Production

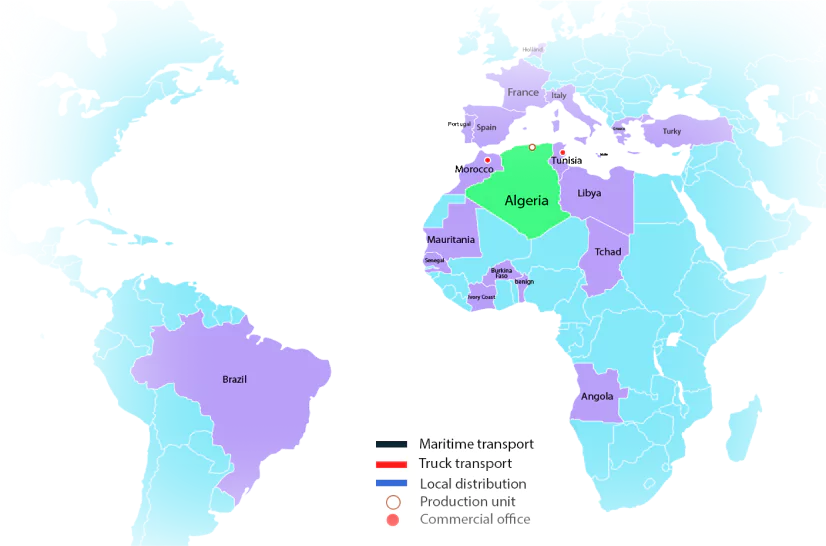

Distribution Efficace

Discover Excellence with Mediterranean Float Glass

Our distribution network goes beyond simple proximity, promoting harmonious collaboration between our teams. This synergy is essential to ensure the quality and precision of our responses, careful monitoring of the supply chain and unwavering consistency in production.

At Mediterranean Float Glass, we are committed to delivering excellence. Discover your dedicated distributor today to access our world-class glass solutions. We are with you every step of the way, ensuring that your needs are met with the utmost reliability and satisfaction.

Quality Management System

To guarantee the performance of its management in terms of Health, Safety, Environment and Quality, MFG has certified its activities for many years by internationally recognized organizations. Thus, production is carried out in accordance with regularly audited production standards.

Serving quality of life and customer satisfaction, the MFG central laboratory obtained a favorable accreditation decision for physicochemical testing of glass following the ALGERAC evaluation (the Algerian Accreditation Body) in accordance with standard ISO/IEC 17025:2005. This accreditation attests to the technical competence of the MFG laboratory in the field of physicochemical analyzes of raw materials and finished flat glass products, as well as the proper functioning of the quality management system.

Process float

The Float Glass Manufacturing Process

Preparation of raw material

Rigorous control is ensured for each raw material before it is put into the oven, according to recognized international standards.

Preparation of the vitrifiable mixture

Composed of all the raw materials used in the manufacture of float glass.

Fooking

Rigorous control is ensured for each raw material before it is put into the oven, according to recognized international standards.

Melt furnace

The oven, built from refractory bricks, can contain up to 2,000 tonnes of glass melted at 1,550°C.

Tin bath

The glass floats on a bath of molten tin. Toothed wheels at the edges of the ribbon propel the glass forward and set the required thickness.

Restaurant

The hanger allows the glass ribbon to cool under carefully controlled conditions. This process releases the internal tensions of the glass and maximizes its potential in terms of mechanical resistance.

Control room

Monitoring of the entire line is done at this level via automatic fault detection, control of glass thickness and constraints as well as optimization of different glass formats.

Cutting system

It is used to cut glass into different dimensions, according to the desired formats.

Vacuum lifts

This system allows glass trays to be stacked directly on racks so that they can then be stored and shipped.

Glass delivery

The trailer, equipped with special suspensions and having a specific design, receives the desk loaded with glass trays (27 tonnes). The assembly is held in position using articulated arms or air cushions.

Contact Nouz

Let's connect

Send the message

Contact details

Loading...